BLOG

Uvlack Coatings: Uses, Benefits, and Applications

In today’s fast-paced industrial landscape, efficiency, durability, and aesthetics define product success. One solution that meets all these demands is Uvlack (UV-Lack), a UV-curable lacquer or varnish widely recognized for its instant curing, long-lasting protection, and versatile finishes. Used in industries such as printing, packaging, furniture, and automotive, this coating technology has transformed how surfaces are protected and presented.

What is Uvlack (UV-Lack)?

Uvlack, or UV-Lack, is a UV-curable lacquer that hardens under ultraviolet light, providing fast curing, durability, and protective glossy, matte, or satin finishes for printing, packaging, furniture, and automotive industries. It is often spelled as UV-Lack, refers to a specialized coating that hardens immediately when exposed to ultraviolet (UV) light. Unlike traditional solvent- or heat-based coatings, this varnish leverages photochemical reactions to cure instantly, saving both time and energy.

Key characteristics include:

- Instant curing with UV radiation.

- Customizable finishes: glossy, matte, or satin.

- Durable protection against scratches, chemicals, and environmental wear.

- Eco-friendly potential due to reduced solvent emissions.

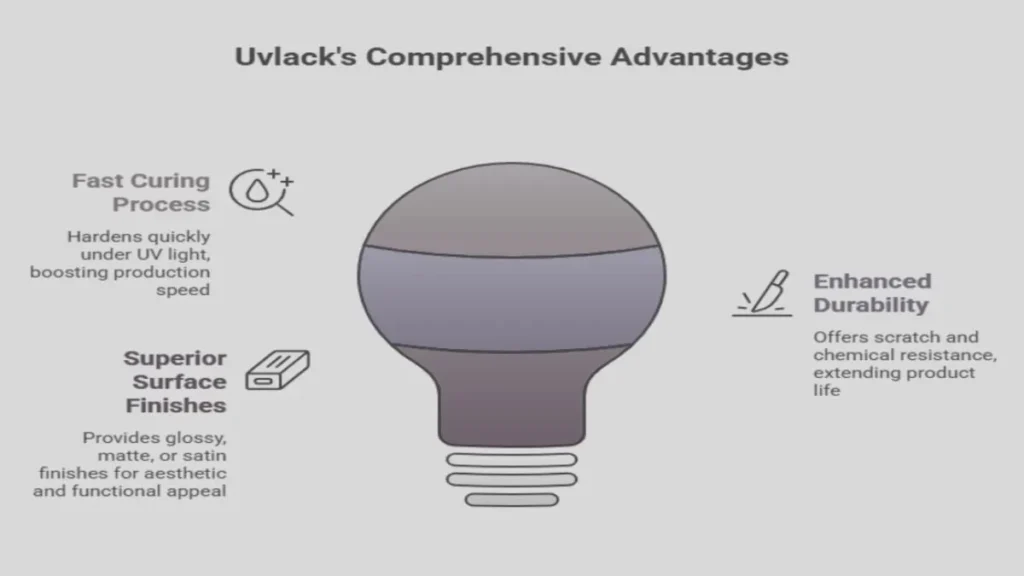

Key Benefits of Uvlack

How Does Uvlack Work?

It works through a process called photopolymerization. Once applied to a surface, it is exposed to ultraviolet (UV) light, which activates special ingredients called photoinitiators. These trigger a chemical reaction that causes the coating to harden almost instantly.

Unlike traditional coatings that need hours to dry, it cures within seconds. The result is a durable, smooth, and protective surface finish with glossy, matte, or satin options.

Comparison: Uvlack vs. Traditional Coatings

| Feature | Uvlack (UV-Lack) | Traditional Coatings |

| Curing Time | Seconds under UV light | Hours to days |

| Durability | High scratch and chemical resistance | Moderate protection |

| Environmental Impact | Low VOC, eco-friendly | Higher VOC emissions |

| Energy Usage | Low (UV lamps/LEDs) | High (heat curing) |

| Finish Variety | Gloss, matte, satin | Limited options |

Applications of Uvlack Across Industries

Uvlack in the Printing Industry

It enhances magazines, brochures, and labels with glossy, matte, or spot finishes. It ensures smudge-proof, durable prints while adding premium visual effects that elevate branding and reader engagement.

Uvlack in the Packaging Industry

In packaging, the ultraviolet curing process provides a luxury appeal for cosmetics, electronics, and food products. Its glossy, matte, or textured finishes improve durability, protect against handling damage, and enhance consumer perception of brand quality.

Uvlack in the Furniture Industry

Furniture manufacturers use the ultraviolet curing process to protect wood and MDF surfaces from scratches, stains, and chemicals. With matte, satin, or glossy finishes, it enhances modern aesthetics while extending the lifespan of furniture.

Challenges and Considerations

While it offers numerous benefits, some challenges need addressing:

- Initial Investment: UV curing equipment can be costly.

- Surface Limitations: Not all materials are compatible with UV coatings.

- Safety Precautions: UV light exposure requires protective measures for workers.

- Maintenance: Lamps and curing equipment require regular upkeep.

Environmental and Sustainability Impact

Sustainability has become a key driver in industrial innovation. It supports eco-friendly practices by:

- Replacing solvent-based coatings with low-emission alternatives.

- Reducing energy consumption due to rapid curing.

- Enabling waste reduction through efficient application methods.

This makes the ultraviolet curing process not just a technological advancement but also a step towards sustainable production practices.

Future of Uvlack Technology

The future of Uvlack technology is focused on sustainability and innovation. Advancements like LED-based UV curing will cut energy use, while bio-based formulations reduce environmental impact. Smart coatings with self-healing or antibacterial features are also emerging.

Industries demand faster, eco-friendly, and versatile finishes. It will continue evolving to meet these needs, especially in luxury packaging, automotive, and electronics, making it a key player in next-generation coating solutions.

FAQs

Q1. Is Uvlack eco-friendly?

Yes, modern UV coatings are low in VOCs and cure quickly, making them more sustainable than solvent-based coatings.

Q2. How does Uvlack cure so fast?

It cures instantly when exposed to ultraviolet light, unlike traditional coatings that require heat or air drying.

Q3. Can Uvlack be applied to all surfaces?

While highly versatile, some materials may require special primers or formulations for compatibility.

Final Thought

Uvlack, or UV-Lack, has revolutionized surface finishing by combining durability, speed, and aesthetic versatility. From printing and packaging to furniture and automotive, its applications highlight its adaptability across industries. With eco-friendly curing and premium finishes, the ultraviolet curing process not only enhances product appeal but also ensures long-lasting protection. As industries continue moving toward sustainable and high-performance solutions, it will remain a cornerstone of modern coating technology.

-

FRIENDSHIP MESSAGES4 months ago

FRIENDSHIP MESSAGES4 months ago100+ Heart Touching Sorry Messages for Friends

-

ANNIVERSARY WISHES8 months ago

ANNIVERSARY WISHES8 months ago100+ Beautiful Engagement Anniversary Wishes Messages and Quotes

-

BIRTHDAY WISHES7 months ago

BIRTHDAY WISHES7 months ago300+ Happy Birthday Wishes for Brother | Heart Touching Happy Birthday Brother

-

BIRTHDAY WISHES8 months ago

BIRTHDAY WISHES8 months ago200+ Unique Birthday Wishes for Your Best Friend to Impress on Their Big Day