BLOG

Sodiceram: High-Performance Ceramic Reinvented

Sodiceram is a cutting-edge ceramic material and brand that integrates sodium-based compounds into its composition to enhance strength, resilience, and aesthetics. More than just a ceramic, it stands as a fusion of science, sustainability, and style—designed to meet the growing demands of modern architecture, industrial efficiency, and artistic expression.

It is excellently developed with passionate contemplation to innovation; Sodiceram is highly acclaimed as having magnificent mechanical strength, thermal stability, and chemical resistance, hence best suited to abundant diverse applications. At homes in factory floors, makers of carpets to interior stablished luxury, in exterior cladding, it is high-performance properties, coupled with environmentally friendly manufacturing have given the product a leading position in the next ceramic age.

Table of Contents

Sustainability Edge

The manufacturing process at Sodiceram conforms to green production in the world. The brand uses the system of closed water loops, up to 40 percent of raw materials are used which are recycled, and low-emission kilns are chosen. In contrast to traditional ceramics that usually are accompanied by a lot of waste, it will result in the fewest wastes and a low amount of carbon emissions. It also has a long life-cycle, which minimizes replacement, thus were in line with sustainable architecture objectives.

Why Choose Sodiceram

- Cost Effectiveness in the Long run: It looks expensive, but in an actual sense, it is cost-effective, since it saves on costs of repair, replacement, and maintenance in the long run.

- Customization in Scale: There are no limits to the creativity of designers and architects, nor is further treatment after the installation.

- Green Certification Friendly: The intention of the projects to receive LEED or other such certificates is also beneficial in that the construction utilizes environmentally-aware building materials such as Sodiceram.

- InnovaPower: Excellent in highly-hygienic environments like hospital or commercial kitchens or spa applications, since it is low-absorbing and antibacterial: it resists bacterial attachment on its surfaces.

Types & Technical Comparison

| Type | Composition Focus | Key Strength | Primary Application |

| Sodiceram Classic | Sodium-Silicate Core | Impact Resistance | Residential Interior Surfaces |

| Sodiceram Industrial | Sodium-Alumina Blend | Thermal + Chemical Resist | Kilns, Furnaces, Chemical Plants |

| Sodiceram Deco | Sodium-Glazed Porcelain | Surface Aesthetic | Walls, Feature Panels |

| Sodiceram Outdoor | Salt-Crystal Infused Clay | Weatherproofing | Exterior Flooring, Façades |

| Sodiceram Pro | Nano-Sodium Composites | Ultra-Durability | High-Traffic Commercial Zones |

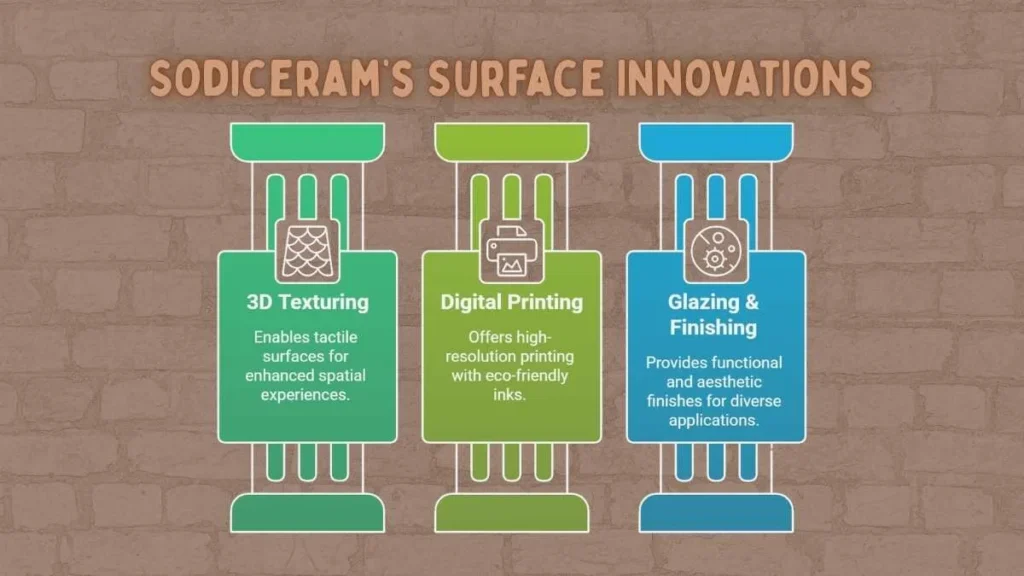

Surface Technologies of Sodiceram

3D Texturing

The breakthrough enables the designers to create surfaces that are felt and can enhance the experiences within spaces. It could be a stone-like or modern wave style, and underneath can be formed in 3D texturing, having an artistic view as well as a purpose of purpose.

Digital Printing

It is compatible with ultra high resolution digital printing with eco-solvent inks, which can enable unlimited design potentiality, whether photorealistic or geometrical patterns, with zero reduction in strength or environmental impact.

Glazing & Finishing

Instead of being solely aesthetic finishes as in the case with traditional ceramics, it has functional finishes. Slippery surfaces with wet applications, antistatic glazes in hospitals, and inspective glazes with thermal insulation are all achievable.

Wide-Ranging Applications

- Architectural facades, wall cladding, and roofing systems

- High-traffic commercial flooring and tiling

- Industrial surfaces for chemical and heat-intensive environments

- Decorative panels and luxury interior designs

- Custom backsplashes and digitally printed feature walls

- Public infrastructure like metros, hospitals, and airports

Market Impact

It has had massive reception in the European, Asian, and Middle East markets. It has a cost advantage and an environmental advantage since it can replace natural stone, as well as conventional ceramics, due to its cost-effectiveness and environmental friendliness. Architectural companies around the globe are gradually integrating it in the design of LEED-certified buildings and cities. Also, as the construction industry moves towards modularity and precise work, Sodiceram, with its digitally flexible characteristics, is an item that is really becoming a staple in a material library as well.

Customers Speak

Amara Shah, Interior Designer (Dubai):

“Sodiceram tiles were a game-changer for our eco-conscious hotel project. The 3D textures and digital prints gave us the freedom to replicate luxury marble without the environmental burden.”

Luca Verani, Plant Engineer (Milan):

“Our chemical processing floor has never lasted this long. Sodiceram Industrial resisted acid spills and high temperatures for over three years without signs of wear.”

Innovation Outlook

The future of it resides in additional nanotechnology integration, which, perhaps, allows even lighter and stronger forms with embedded smart capabilities. R&D laboratories design sodium-crystal structures that improve buffooning cleaning and even heat-storage in passive solar designs. The process of smart construction keeps increasing, and Sodiceram is likely to be on the edge of this revolution.

Conclusion

Sodiceram bridges the gap between science of materials, design creativity, and environmental sustainability. It is sodium saturated to increase performance in every category. It includes: mechanical strength, chemical resistance, thermal endurance, and fosters low-impact production. Designing a residential makeover or specifying an industrial-grade type of facility is an idea that you can use because of the durable, eco-aligned, and stunning appearance it conveys.

Its readiness to the new technologies of such products as digital surface rendering and energy-efficient fabrications certifies that Sodiceram is not only a product, but a material, developed for tomorrow.

-

FRIENDSHIP MESSAGES5 months ago

FRIENDSHIP MESSAGES5 months ago100+ Heart Touching Sorry Messages for Friends

-

ANNIVERSARY WISHES8 months ago

ANNIVERSARY WISHES8 months ago100+ Beautiful Engagement Anniversary Wishes Messages and Quotes

-

BIRTHDAY WISHES8 months ago

BIRTHDAY WISHES8 months ago300+ Happy Birthday Wishes for Brother | Heart Touching Happy Birthday Brother

-

BIRTHDAY WISHES8 months ago

BIRTHDAY WISHES8 months ago200+ Unique Birthday Wishes for Your Best Friend to Impress on Their Big Day