BUSINESS

What Is a Protocolo Operacional Padrão (POP)?

A Protocolo Operacional Padrão (POP), or Standard Operating Procedure (SOP) in English, is a comprehensive, written document that outlines a series of instructions intended to ensure the consistent execution of routine tasks and operations. Designed for clarity and replicability, POPs serve as a foundational tool in organizations where precision, safety, and uniformity are non-negotiable.

From hospitals and factories to classrooms and public service offices, Protocolo Operacional Padrão is used to standardize processes, minimize errors, and maintain regulatory compliance. These protocols not only reduce the learning curve for new employees but also act as a reference for seasoned professionals, enabling organizations to function efficiently under a unified framework.

Table of Contents

Why POP Matters

Quality is determined by consistency. In the sectors where human error may result in disastrous outcomes, e.g., in the fields of healthcare or manufacturing, even a minor deviation from a process may turn into a costly or even hazardous condition. Protocol Operacional Padrão (POPs) eliminates this, due to its step-by-step clarity, every action that takes place will have the same trusted protocol, no matter what person performs it.

Implementation Strategy

The process of developing a successful Protocolo Operacional Padrão needs to be a highly structured process that complies with the operating reality within an organization. This is a typical flow of how a Protocolo Operacional Padrão (POP) development process goes:

1. Identification of the Task

The choice of a task that has to be standardized should start by choosing a job that is often repetitive and prone to error, or a job that is very important to service quality. This may be any kind of cleaning procedures in a hospital or machine calibration in a factory.

2. Process Mapping

All the steps of the task are sketched in a chronological pattern. This is the inputs, activities, the persons to carry it out, and the anticipated output. Depicting the workflow visually can be performed with the help of a tool such as a flowchart or a diagram of the process.

3. Documentation

After being mapped, all the steps are written in simple, clean language. It contains any tools, safety precautions, time specifications, or other references of compliance. The structure is not of prime importance; only clarity.

4. Validation

A real-world situation or pilot group is then organized, whereby the draft Protocolo Operacional Padrão is put to the test. Clear, practical, and efficient assessments are achieved through observations. All stakeholders are asked to provide feedback.

5. Approval and Implementation

On certification, a formal review of the document is conducted, and it is certified by the appropriate bodies or compliance teams. It is then utilized by the personnel with any relevant training.

6. Periodic Review

Protocolo Operacional Padrão (POP) does not remain as it is. It has to be reviewed periodically, particularly in cases where regulations vary or equipment is revised to have relevance and be accurate.

The ordered approach would also be effective in ensuring POPs are not merely functional, but also realistic and scalable, thus being a tool that will be used in daily operational activities.

Comparison Table: POP vs SOP vs WI

| Feature | POP (Protocolo Operacional Padrão) | SOP (Standard Operating Procedure) | WI (Work Instruction) |

| Focus | Task standardization | Broad policy & operational scope | Highly detailed instructions |

| Language | Simple, functional | Technical, policy-aligned | Extremely specific |

| Usage Level | Operational | Managerial + Operational | Executional |

| Industries Commonly Used | Healthcare, Manufacturing, Public | Corporate, Government, Logistics | Engineering, Assembly |

| Training Integration | High | Medium | Very High |

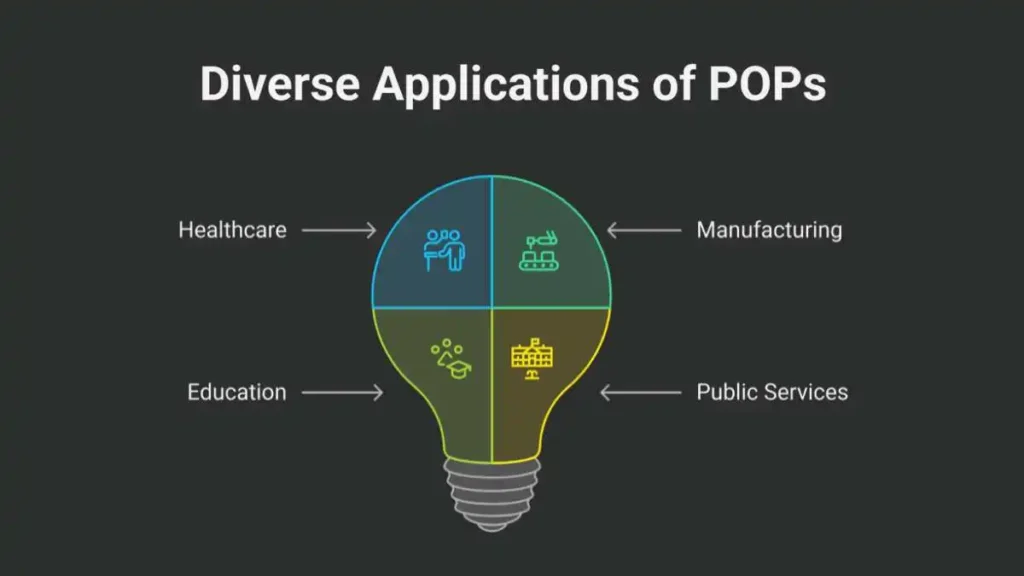

Uses in multiple sectors

Protocolo Operacional Padrãos (POPs) are instrumental across industries where precision, safety, and consistency are critical. Here’s how different sectors benefit:

Healthcare

- Standardizes medication administration, patient handovers, and surgical protocols.

- Reduces malpractice risks and enhances patient safety.

Manufacturing

- Streamlines assembly-line tasks and machine maintenance

- Improves product consistency and reduces defects

Education

- Unifies lesson planning and curriculum execution across departments.

- Provides protocols for exam administration and evaluation.

Public Services

- Standardizes citizen-facing services and documentation processes

- Ensure compliance during large-scale operations like elections

Key Benefits

- Reduces human error: Clear instructions help eliminate guesswork.

- Improves efficiency: Tasks are performed faster and more accurately.

- Enhances compliance: Ensures processes meet regulatory and quality standards.

- Simplifies training: New employees learn procedures more quickly.

- Promotes accountability: Clear role definitions and task responsibilities.

- Boosts quality assurance: Ensures outputs meet a consistent standard.

Common Mistakes

Although Protocolo Operacional Padrãos (POPs) are beneficial, they may not be successful when poorly implemented. The most common pitfall is to make the documents overly complex, which may overwhelm the staff and compromise compliance with them. Failure also happens when one uses vague words or when they do not change protocols upon changes in technology.

The second blind spot would be noting the feedback given by the frontline employees. A Protocolo Operacional Padrão, authored by administrators and never tested by practitioners, is usually not realistic. Finally, when there is no accountability framework that surrounds the protocol, then it will be disregarded.

Long-Term Impact

In the long term, a well-enforced Protocolo Operacional Padrão (POP) induces a self-disciplined organization culture geared towards quality and not the performance of individuals. It promotes the spirit of continuity and accountability, and teams are also agile and are confident both in normal and critical circumstances. As an example, a hospital could expect a decrease in the number of medical errors and better patient outcomes, and a factory could have less downtime and better product quality. Such advancements not only uplift the level of internal efficiency but also augment levels of customer credibility, regulatory adherence, and brand recognition.

Conclusion

A Protocolo Operacional Padrão (POP) is not only a document, it is an organizational cultural and procedural change towards excellence. It is an aggressive way of error handling and training, and efficiency in operations. The need to have standardized, proportional, and controlled processes increases with the change of businesses and institutions.

Protocolo Operacional Padrãos (POPs) are indispensable in achieving this transformation. They empower teams, safeguard quality, and anchor organizations in an ever-changing environment. With their strategic implementation, any organization—regardless of size or industry—can cultivate a system of reliability, repeatability, and success.

-

FRIENDSHIP MESSAGES4 months ago

FRIENDSHIP MESSAGES4 months ago100+ Heart Touching Sorry Messages for Friends

-

ANNIVERSARY WISHES8 months ago

ANNIVERSARY WISHES8 months ago100+ Beautiful Engagement Anniversary Wishes Messages and Quotes

-

BIRTHDAY WISHES7 months ago

BIRTHDAY WISHES7 months ago300+ Happy Birthday Wishes for Brother | Heart Touching Happy Birthday Brother

-

BIRTHDAY WISHES8 months ago

BIRTHDAY WISHES8 months ago200+ Unique Birthday Wishes for Your Best Friend to Impress on Their Big Day